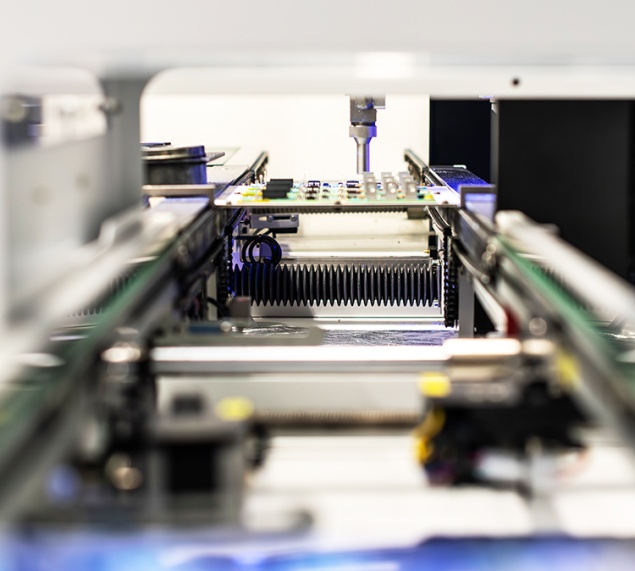

After soldering, the PCB is often cleaned to remove any flux residue or dirt. For this purpose, we use the Injet 388 TWIN CRRD automatic cleaning machine.

The InJet® 388 TWIN CRRD "Sausage Dog" has been developed primarily for high-capacity and precise cleaning of boards after soldering. Cleaning takes place in the first inlet chamber, after which the cleaned part is automatically transported to the central pass-through camber, where the first pre-rinsing process takes place. The third, and last, outlet chamber is designed for the final rinsing and drying process. Both chambers (inlet and outlet) can be used simultaneously, which increases the machine capacity and reduces cross-contamination compared to single-chamber devices.

Selective coating of assembled PCBs is a technology allowing you to apply varnish or sealing material only to certain areas of the PCB, while other areas remain uncoated. This is done to protect sensitive parts of the board from environmental influences and mechanical wear.

Selective coating on a PVA Delta 6 machine offers a number of benefits, including increased quality, manufacturing efficiency, and protection of sensitive PCB components. It is a key technology in modern electronics manufacturing that helps ensure the reliability and longevity of electronic devices.

Do you have questions, comments or are you just curious? We are here for you! Contact us through the channels below or using the form.